Today, I want to talk a bit about compressor types used in data center cooling systems and how the differences between them can affect overall design. It’s also important to understand which compressor type fits best with which kind of system layout or capacity.

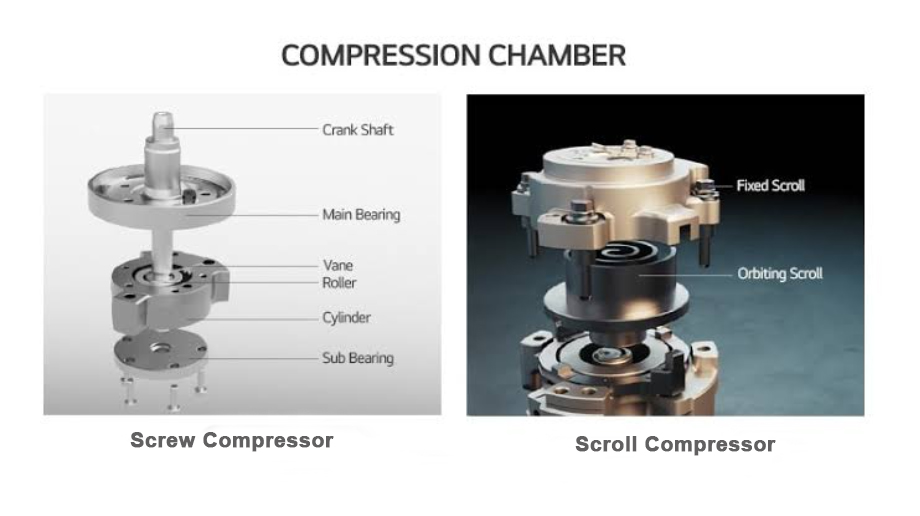

Let’s start by understanding how these compressors actually work. Scroll compressors operate using two spiral-shaped scrolls—one fixed and one that moves in an orbiting motion. This design compresses the refrigerant in a smooth and quiet way. Because of their simple and compact structure, they are often used in smaller systems or modular solutions.

Screw compressors work differently. They use two interlocking helical screws to compress the refrigerant in a continuous, smooth flow. This type of compressor is more suitable for higher loads and is commonly found in industrial HVAC systems and large-scale chillers. The operation is stable, reliable, and much more efficient when the cooling demand is high.

As I mentioned, the most efficient compressor depends on the system design. For example, if your data center has relatively low capacity, scroll compressors are usually a better fit. They perform better under partial loads and can handle frequent start-stop cycles without issues. So if the cooling system is expected to turn on and off often or run at variable loads, scroll compressors offer a solid, efficient choice.

However, if you’re designing a high-capacity data center, the better option is definitely the screw compressor. In fact, it’s quite rare to find a high-capacity chiller that uses scroll compressors—most of them come equipped with screw compressors by default. That’s because the design and working principles of screw compressors are better suited to high cooling loads.

From my experience, I’ve seen cases where end users chose in-row or large quantities of DX in-room cooling systems with scroll compressors for high-capacity data centers. This kind of decision often leads to problems later. I’ll go into more detail on that topic in another post, but to stay focused here: in-row and DX in-room units typically use scroll compressors, and they are really only intended for small or medium-scale environments. When used in larger systems, they can cause multiple issues—like service disruptions, lower energy efficiency, and poor cooling performance overall.

Luckily, this kind of mismatch doesn’t happen very often in professional data center projects. In most large-scale setups, the cooling system is based on chilled water chillers that use screw compressors. These compressors offer more stable operation thanks to their continuous compression cycle rather than a pulse-based approach. This leads to greater efficiency, especially when cooling demand is high.

When screw compressors are combined with variable speed drive (VSD) systems, energy consumption is optimized even further. They adjust their speed according to the system’s needs, which reduces wasted energy and improves performance per ton of cooling.

Of course, there’s always an exception. In systems where frequent start-stop cycles are required—like smaller data centers or modular edge setups—scroll compressors might actually be more efficient. Their ability to handle cycling without losing performance makes them a valuable option in those cases. modular edge setups—scroll compressors might actually be more efficient. Their ability to handle cycling without losing performance makes them a valuable option in those cases.

I will reach out to another design points in my upcoming blog posts. Wishing you a smooth path ahead—may everything in your life run as smoothly and beautifully as a well-designed data center. Here’s to success and happiness!

Yorum bırakın